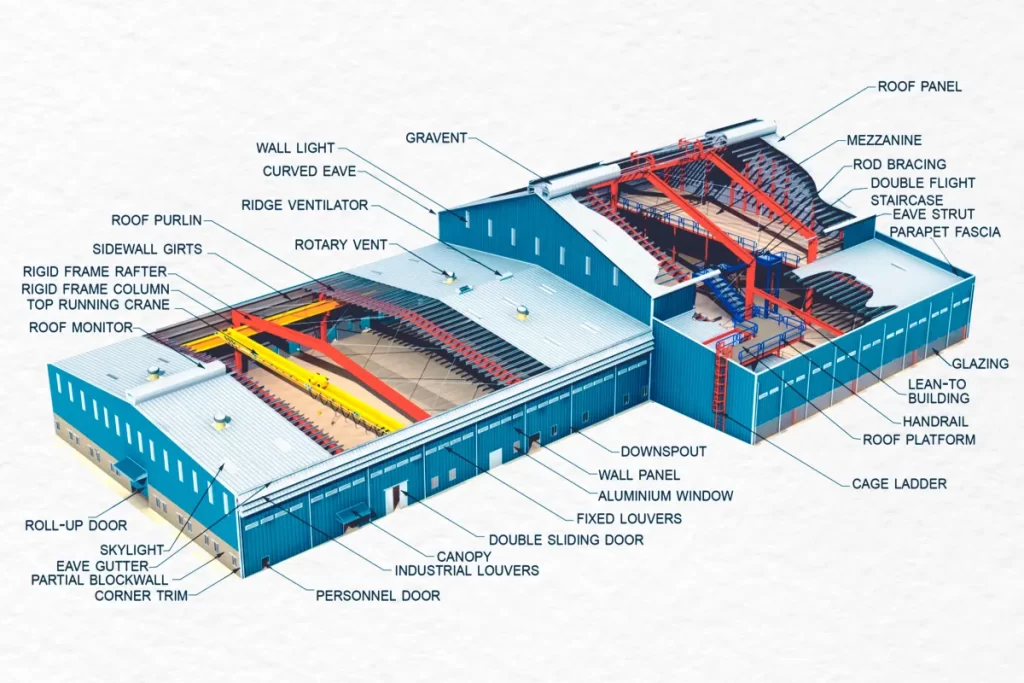

A pre-engineered building, often abbreviated as PEB, is a construction concept where the structural components of a building are designed and manufactured in a factory before being assembled at the construction site. This approach is quite different from traditional construction methods where components are fabricated on-site.

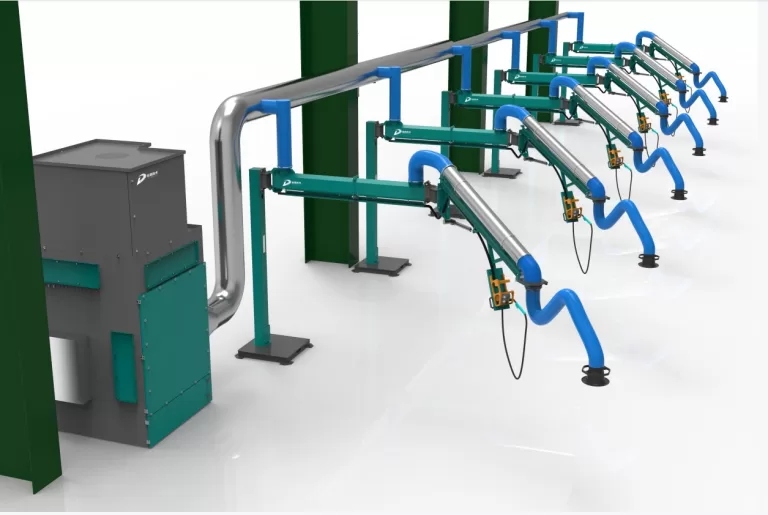

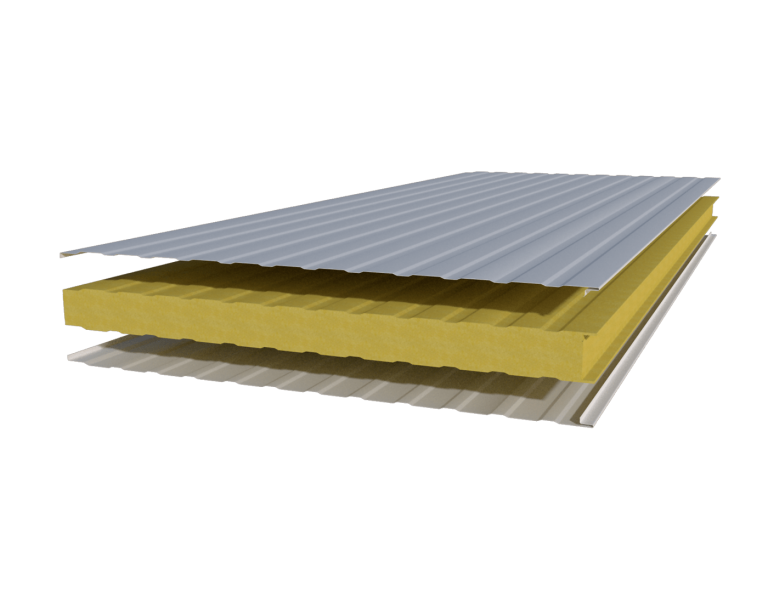

In a pre-engineered building, the primary components, such as columns, beams, roof trusses, and wall panels, are manufactured to precise specifications in a controlled environment. These components are then transported to the construction site and assembled using bolts and fasteners.

Why choose pre-engineered steel building?

- Cost-Effective: PEBs are often more cost-effective than traditional construction because they reduce material waste, labor costs, and construction time.

- Faster Construction: Since the components are pre-engineered and fabricated in advance, the assembly process is much faster than conventional construction. This can be especially beneficial for projects with tight timelines.

- Quality Control: Manufacturing components in a factory allows for strict quality control measures to be in place. This results in higher precision and consistency in the construction.

- Flexibility: Pre-engineered buildings are highly customizable and can be tailored to suit various architectural designs and functional requirements. It is easy to expand in the future and low cost for transportation.

- Energy Efficiency: PEBs can be designed with energy-efficient features, such as insulation and daylighting, to reduce long-term operating costs.

- Sustainability: The controlled manufacturing process can lead to reduced material waste, making PEBs a more sustainable construction option.

Pre-engineered buildings are commonly used for a wide range of applications, including warehouses, industrial facilities, commercial buildings, and even some residential projects. They have gained popularity in the construction industry due to their efficiency and cost-effectiveness.