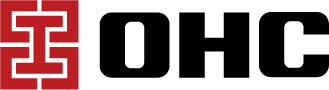

Portal Frame System

A portal frame system is a structural framework commonly used in the construction of buildings, particularly in industrial and commercial applications. It consists of rigid frames that support the building’s roof and walls. The OHC portal frame system is ideal for applications from small to large, simply designed for faster construction and affordability.

It’s important to note that the design and engineering of portal frame systems should be carried out by qualified professionals to ensure the safety and performance of the structure. The choice of structural system depends on factors such as building purpose, location, span requirements, and budget considerations.

Features and Benefits

- Rigid Frames: Portal frames are made up of rigid vertical columns and horizontal beams. These frames are designed to resist lateral loads such as wind and seismic forces.

- Clear Span: One of the significant advantages of portal frame systems is their ability to provide clear spans without the need for interior columns or supports. This allows for open and flexible interior spaces, making them suitable for various applications.

- Efficient Use of Materials: Portal frames are efficient in terms of material usage. The frames can be designed to carry heavy loads while minimizing the amount of steel or other structural materials required.

- Versatility: Portal frame systems can be adapted to different architectural styles and can accommodate various cladding materials, including metal, concrete, or glass.

- Cost-Effective: These systems are often cost-effective for medium to large span buildings. They require fewer materials compared to other structural systems and can be erected quickly, reducing labor costs.

- Ease of Construction: Portal frame systems are relatively easy to construct, and the prefabrication of components can further streamline the construction process.

- Flexibility: They allow for future expansion or modification of the building since interior columns are not required. This makes them suitable for warehouses, factories, and industrial facilities where the layout may change over time.

- Aesthetic Possibilities: Portal frames can be designed to create visually appealing buildings, especially when combined with architectural features and cladding options.

- Structural Integrity: When designed and constructed correctly, portal frame systems exhibit high structural integrity, ensuring the safety and stability of the building.

- Load Distribution: Portal frames efficiently distribute vertical and horizontal loads, which is crucial in areas with high wind or seismic activity.

- Load-Bearing: The primary steel system is the load-bearing framework of the building, responsible for supporting the weight of the building itself, as well as any additional loads such as occupants, equipment, and environmental forces.

- Structural Integrity: It is designed to provide structural integrity and stability to the entire building, ensuring that it can withstand various loads, including gravity loads (such as dead and live loads) and lateral loads (such as wind and seismic forces).

- Customization: Primary steel systems are highly customizable to meet the specific requirements of a building’s design, including span lengths, load-carrying capacities, and architectural aesthetics.

- Material Selection: The choice of materials for the primary steel system, such as carbon steel or structural steel, is made based on factors like strength, durability, and cost-effectiveness.

- Clear Span: Depending on the design, primary steel systems can provide clear spans without the need for interior columns, creating open and flexible interior spaces.

- Efficient Use of Materials: Engineers strive to design primary steel systems that use materials efficiently, optimizing the use of steel or other structural materials to minimize waste and cost.

- Load Transfer: The primary steel system efficiently transfers loads from the building components (such as floors and roofs) to the foundation, ensuring that the building remains stable and safe.

- Connection Details: The connections between steel members are crucial for the overall performance of the primary steel system. Properly designed connections ensure structural integrity and safety.

- Fire Resistance: Depending on building codes and safety requirements, primary steel systems may need to be fire-resistant or protected with fireproofing materials to maintain their structural integrity in case of fire.

- Foundation Support: The primary steel system is anchored to the building’s foundation, which serves as the base for distributing the building’s loads to the ground.

- Quality Control: Fabrication and construction of the primary steel system require strict quality control measures to ensure that the components are manufactured and assembled correctly.

- Compliance with Codes and Standards: Design and construction of the primary steel system must adhere to local building codes, industry standards, and safety regulations to ensure the safety and integrity of the building.

- Seismic Considerations: In regions prone to earthquakes, the primary steel system may incorporate seismic-resistant design features to enhance the building’s earthquake resilience.

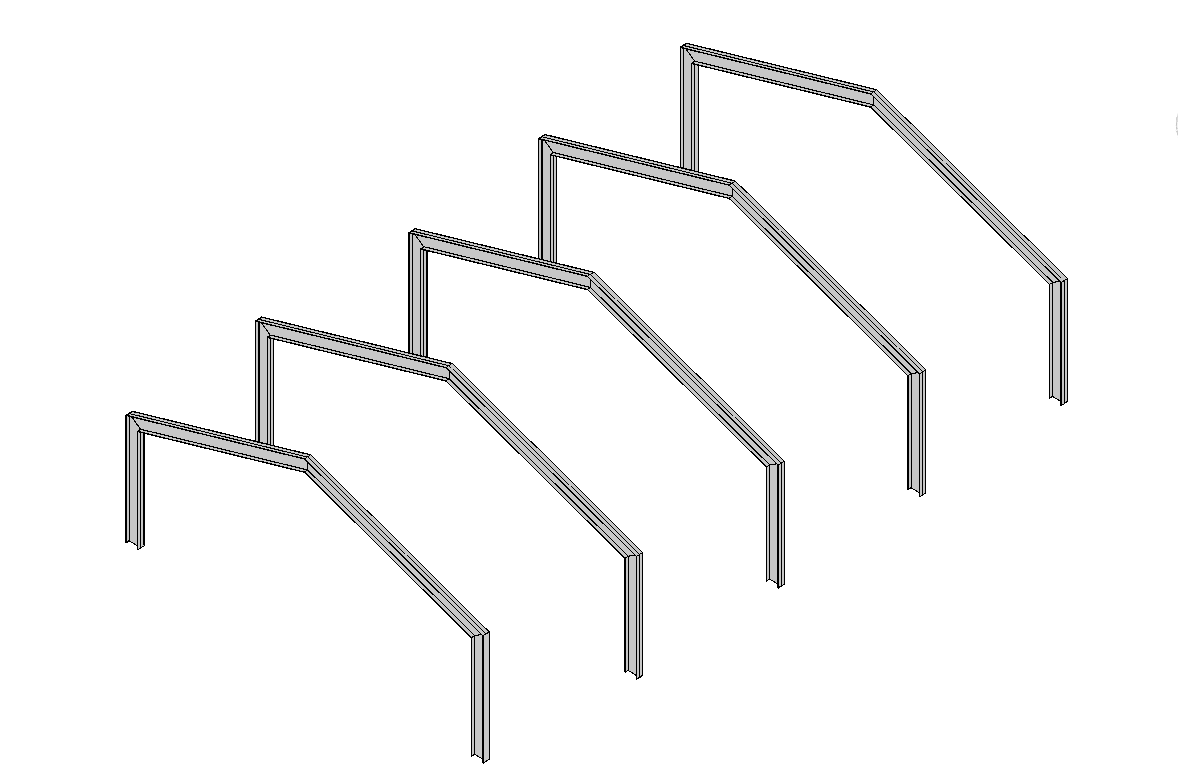

- Support for Building Components: The secondary steel system supports various building components, such as cladding, roofing, mezzanines, catwalks, and equipment. It helps distribute the loads from these components to the primary steel structure.

- Architectural Flexibility: Secondary steel elements are often used to create architectural features such as canopies, awnings, balconies, and decorative elements. This enhances the aesthetic appeal of the building.

- Non-Structural: Unlike the primary steel system, the secondary steel system is typically non-structural. It is not responsible for the primary load-bearing capacity of the building but serves other functional and aesthetic purposes.

- Cladding Support: Secondary steel members, such as purlins and girts, provide support for exterior cladding materials, such as metal panels, curtain walls, or insulation.

- Roof Support: Secondary steel elements, including roof purlins and joists, support the roof structure, such as roof decking, insulation, and roofing materials.

- Mezzanines and Catwalks: In multi-level buildings or industrial facilities, secondary steel is used to create mezzanines, catwalks, and elevated platforms for additional workspace, storage, or access.

- Stairs and Handrails: Secondary steel components are often used to construct stairs, handrails, and guardrails, ensuring safe access and circulation within the building.

- Bracing and Stability: In some cases, secondary steel elements may include bracing or diagonal members that provide additional stability to the building, especially in regions prone to seismic activity.

- Customization: Secondary steel elements can be customized to meet specific architectural and functional requirements. They can be designed to accommodate various loads and aesthetic preferences.

- Material Selection: Similar to the primary steel system, secondary steel components can be made from materials such as carbon steel or structural steel, depending on their intended use and the building’s design.

- Ease of Installation: Secondary steel components are often prefabricated for ease of installation, which can help reduce construction time and costs.

- Integration with Primary Steel: Proper coordination and integration between the primary and secondary steel systems are essential to ensure that the building functions as intended and meets safety standards.

- Insulation and Weatherproofing: Secondary steel elements can also play a role in the installation of insulation and weatherproofing materials, helping to maintain the building’s thermal performance and weather resistance.

- Maintenance Access: In commercial and industrial buildings, secondary steel systems may include access platforms and walkways for maintenance personnel to reach equipment and systems.

- Compliance with Codes: Like the primary steel system, the design and construction of the secondary steel system must comply with local building codes and standards.

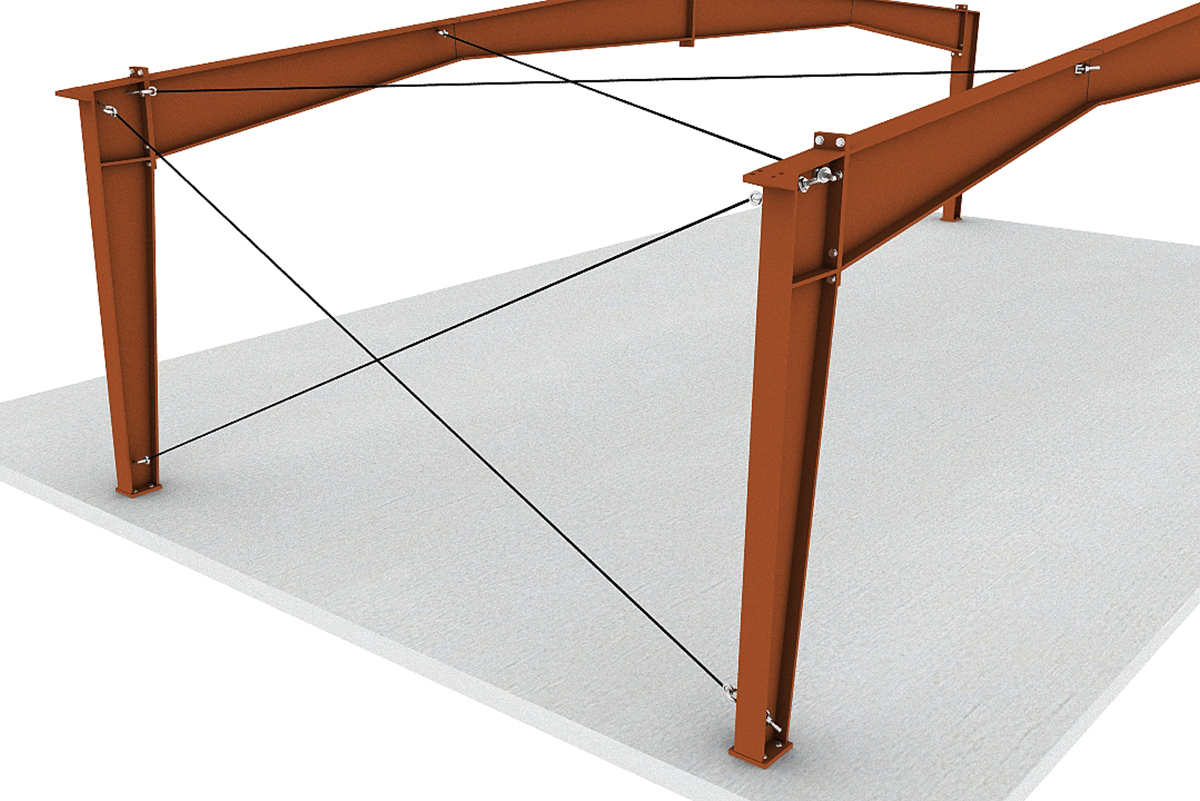

- Lateral Load Resistance: Building bracing systems are primarily designed to resist lateral loads, which can push or pull on the building’s structure. These loads can occur during windstorms or seismic events.

- Stability Enhancement: Bracing enhances the overall stability of a building, preventing excessive lateral movement or swaying, which can be uncomfortable or even dangerous for occupants.

- Types of Bracing: There are several types of bracing systems, including diagonal braces, shear walls, moment frames, and eccentric bracing. The choice of bracing type depends on factors such as building design, local building codes, and anticipated loads.

- Material Selection: Bracing elements can be made from various materials, including steel, concrete, and wood. The material choice depends on structural requirements and design considerations.

- Strategic Placement: Bracing elements are strategically placed throughout the building to ensure that they effectively distribute and resist lateral loads. This placement is determined by structural engineers during the design phase.

- Architectural Considerations: Bracing elements can be integrated into the architectural design of a building, either as visible features or concealed within walls and partitions, depending on the desired aesthetics.

- Load Transfer: Building bracing systems transfer lateral loads from the building’s upper floors and roof to the foundation, ensuring that the building remains stable and safe.

- Seismic Resistance: In regions prone to earthquakes, seismic bracing systems are designed to provide additional resistance to lateral forces, helping the building withstand ground motion and seismic events.

- Wind Resistance: Bracing systems are also crucial for wind resistance, especially in tall or exposed buildings. They help prevent excessive sway and ensure the building remains structurally sound during high winds.

- Compliance with Building Codes: Building bracing systems must comply with local building codes and regulations, which specify design requirements and performance standards to ensure the safety of occupants.

- Connection Details: The connections between bracing elements and the rest of the building’s structure are critical for the overall effectiveness of the bracing system. Properly designed connections ensure that forces are transferred as intended.

- Maintenance: Building owners and managers should regularly inspect and maintain bracing systems to ensure their continued effectiveness. Any damage or deterioration should be addressed promptly.

- Design Flexibility: Structural engineers have the flexibility to design bracing systems that meet the specific needs of a building, taking into account factors such as building height, location, and anticipated loads.

- Fire Resistance: Depending on local regulations and building codes, bracing elements may need to be fire-resistant or protected with fireproofing materials to maintain their structural integrity in case of fire.

Similar Steel Structure Systems

Interested in our systems?

Our engineers will provide the most suitable solutions for your project.