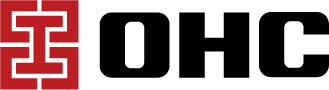

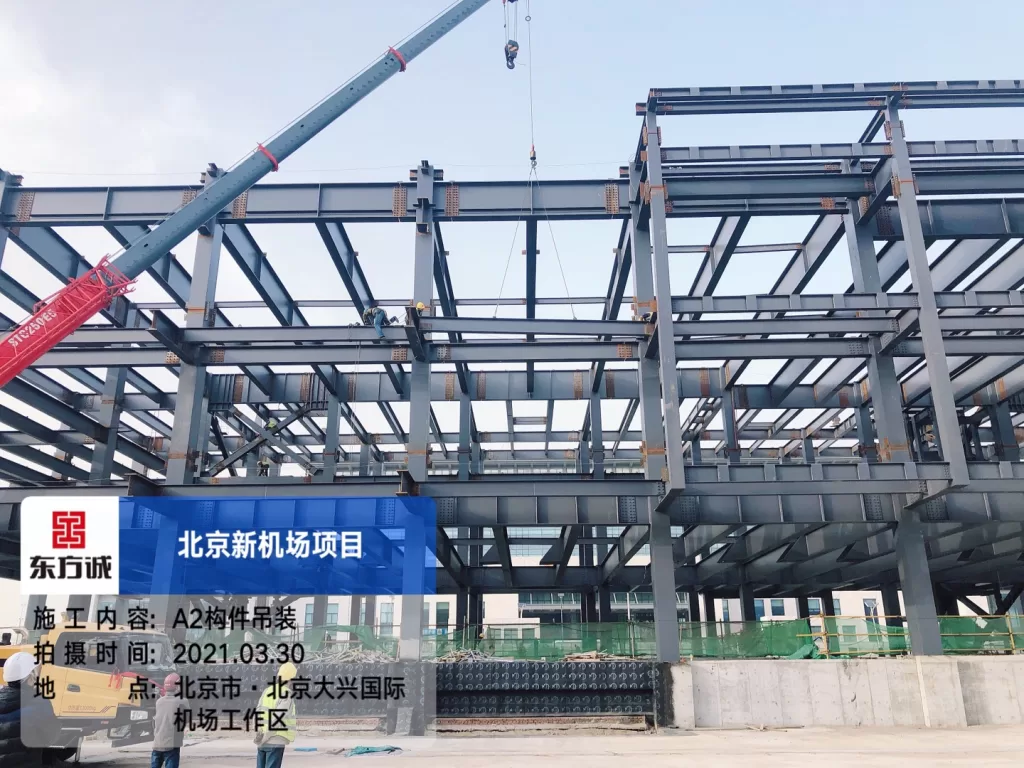

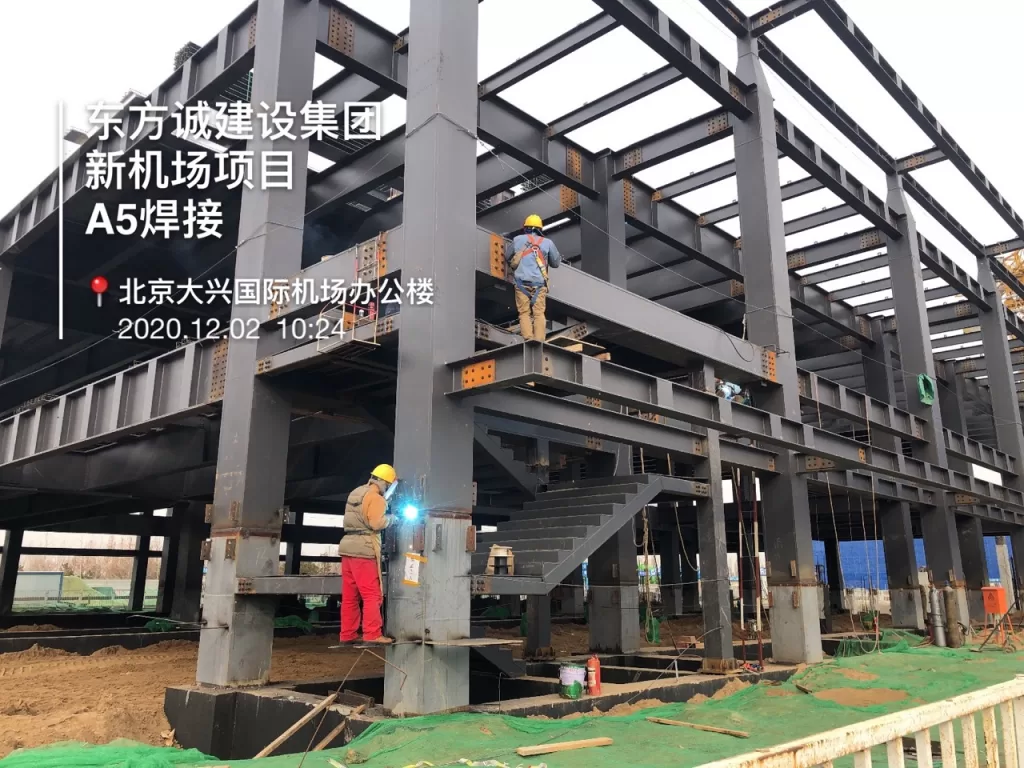

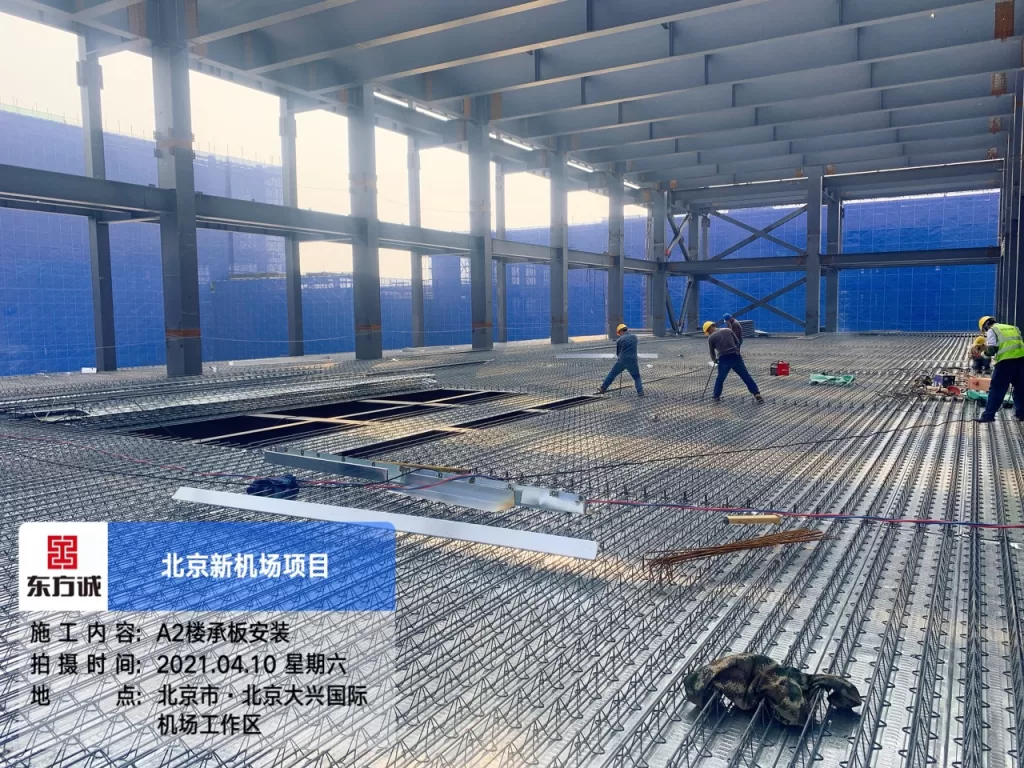

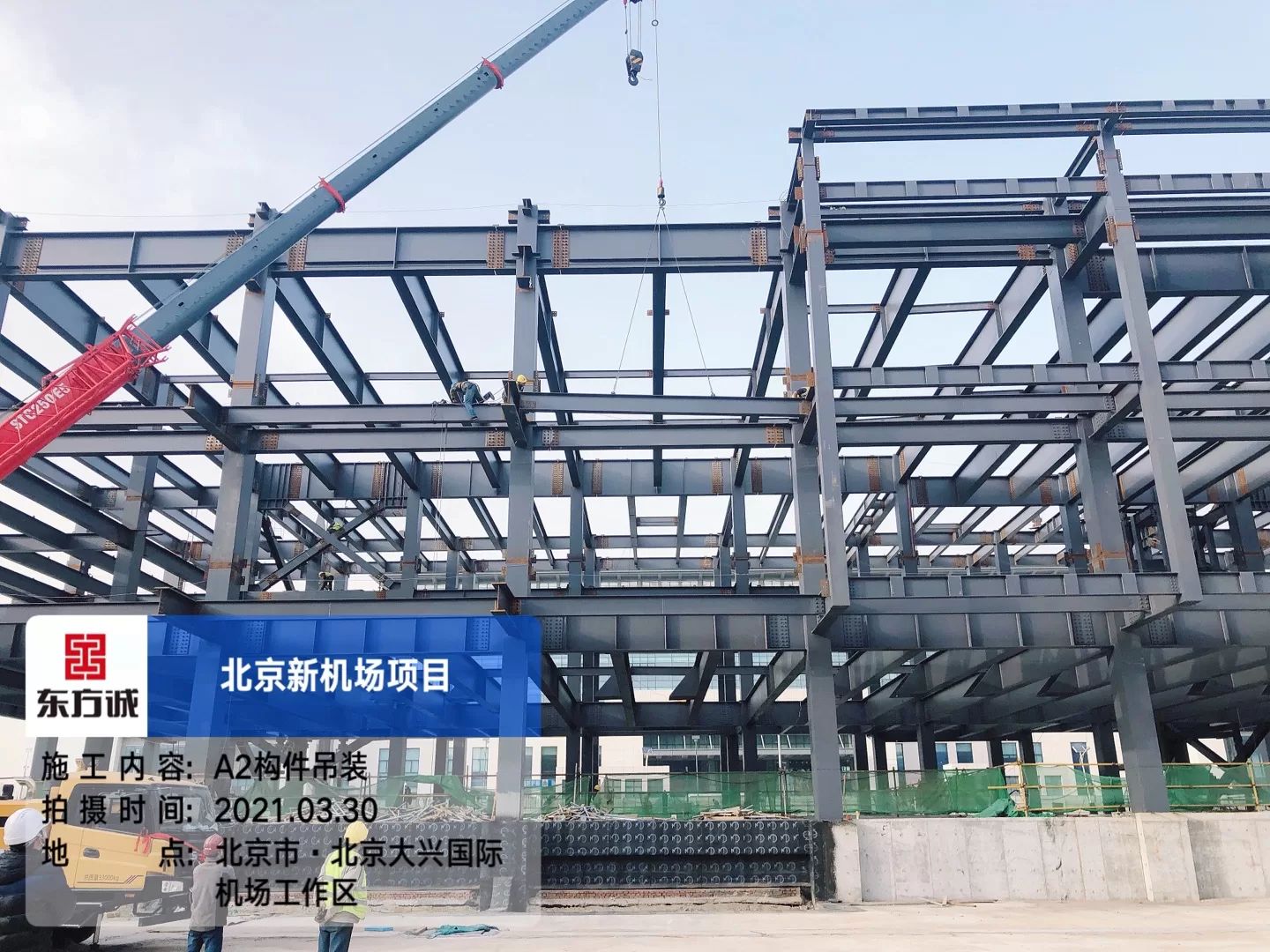

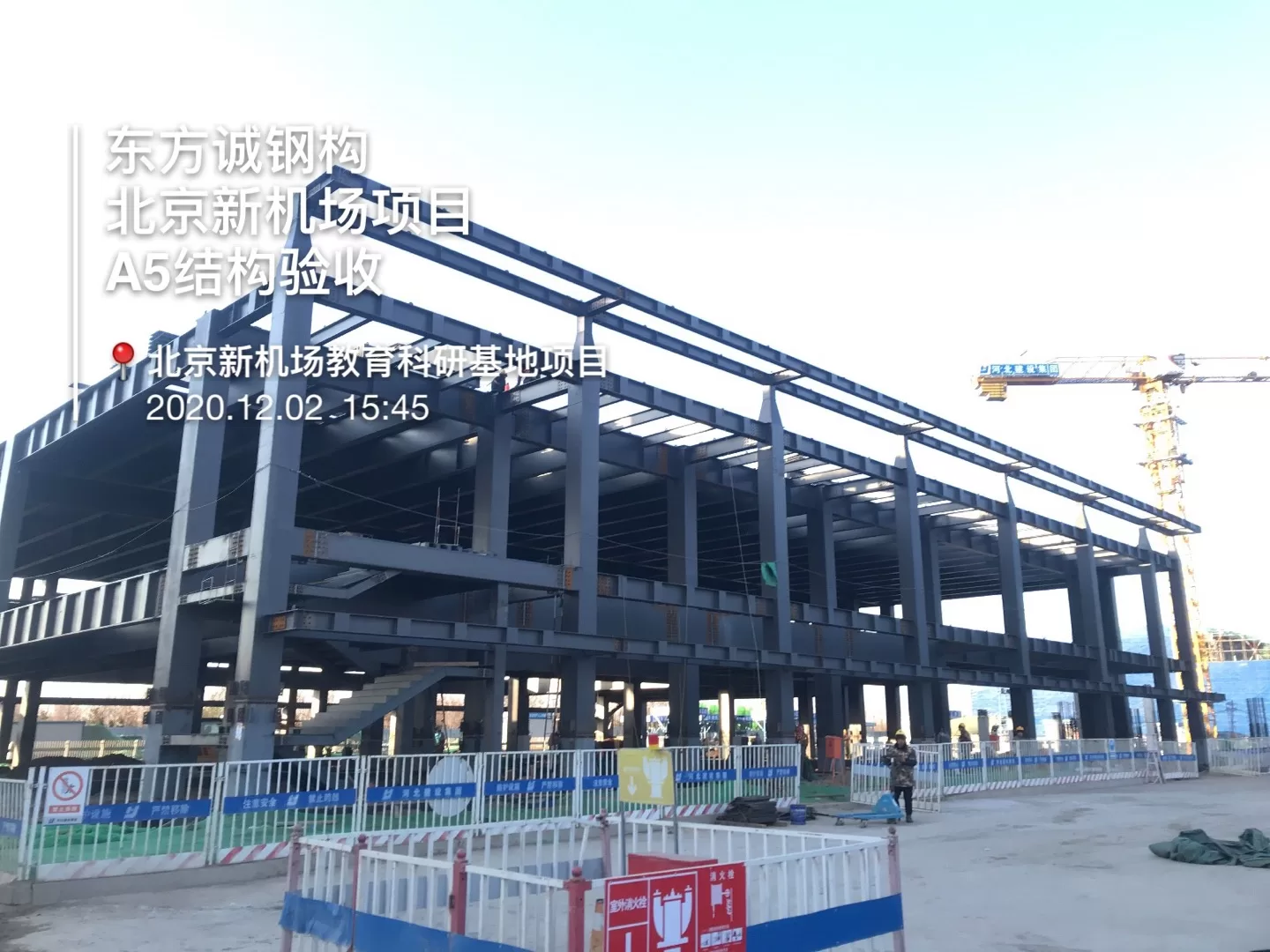

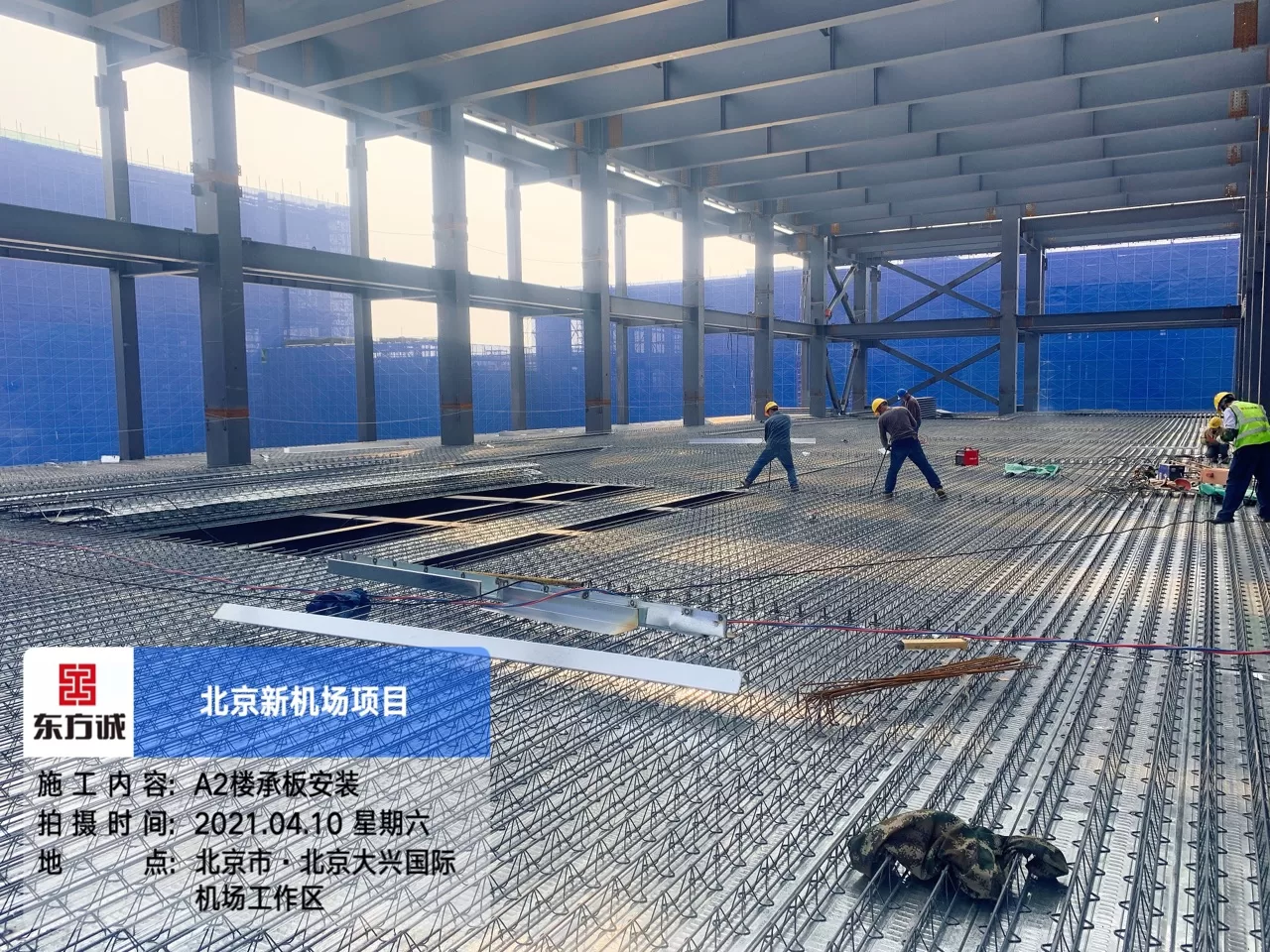

Project Photos

Project Specs

| Client: | Capital Airport Group Corporation |

| Location: | Beijing, China |

| Area: | 84,780 m2 |

| Period: | 2021 |

| Products: | Steel Frame System, Welded Box Column System |

Project Overview

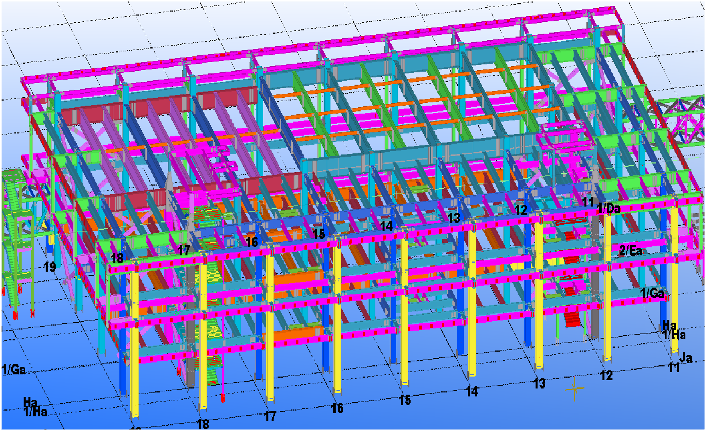

The deepening design of this project requires consideration of multiple factors, such as the connection between steel structures and steel bars, the connection with buckling supports, the rooting of curtain wall keels, and the segmentation of on-site site constrained components.

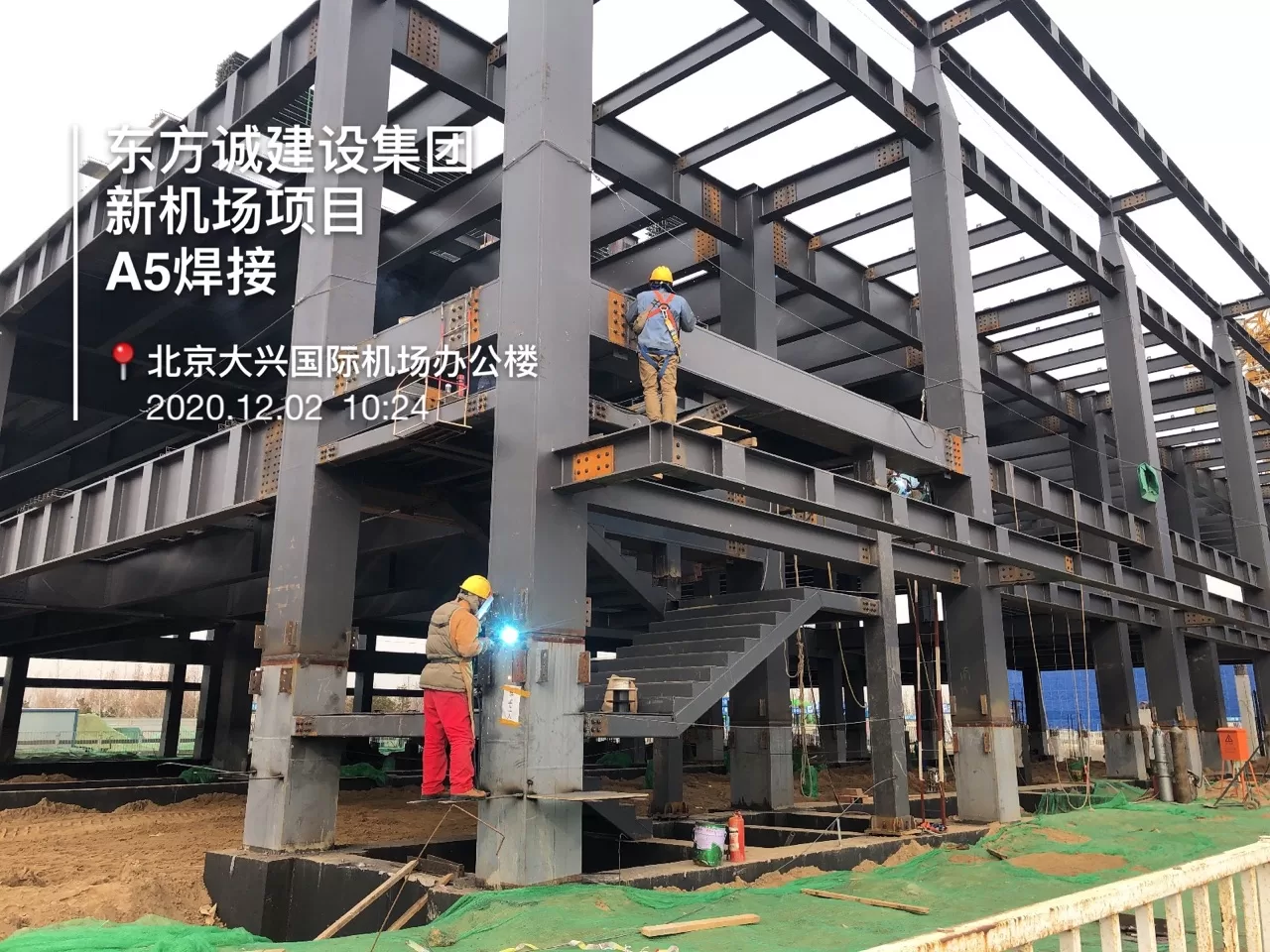

The welding quality requirements for this project are high, and all full penetration welds are first level welds, which is difficult to weld. The gap between the cross pillar wing plates is small and all are first level welds, making it difficult to operate and ensure the welding quality. The welding quantity is very large, and the construction period is also very tight.

The maximum weight of components in this project is 12.9 tons, with a maximum span of 25 meters. The site is relatively narrow, and it is necessary to reasonably organize shipment and cooperate with on-site installation. The maximum cross-section of the on-site welded components is a box beam of 1400 * 800 * 26 * 32. The welding quantity is large, and the full penetration weld seam is of first grade quality with high requirements, and the operation is difficult. In addition, during winter construction, attention should be paid to preheating before welding and insulation after welding. The A4 building is a rigid structure that requires cross construction with civil engineering, which is difficult to construct. There are many professional collaborations and cross operations. Both the truck crane and tower crane on the top floor of Building A4 cannot be lifted in place, and a sliding plan needs to be adopted.