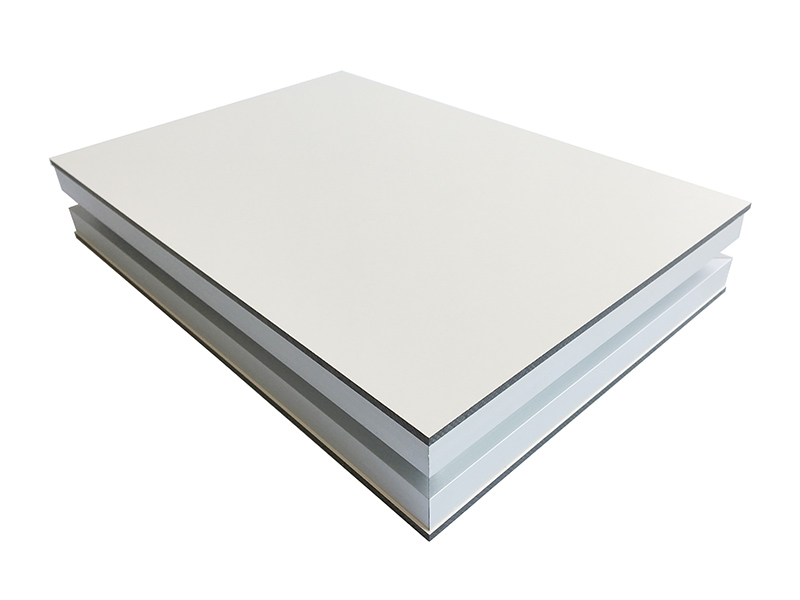

Clean Room Sandwich Panels

Our expertise in cleanrooms allows us to meet the needs of your particular sector, whether that is pharmaceutical, medical, semi-conductor, biotechnology, cosmetics or high-tech.

Features and Benefits

- Flame retardant, soundproof and environmentally friendly.

- Made up of two layers of metal panels and a functional material from the middle.

- Easy installation, light weight and environmental protection.

- The functional materials used for filling can be chosen according to different environments and production requirements.

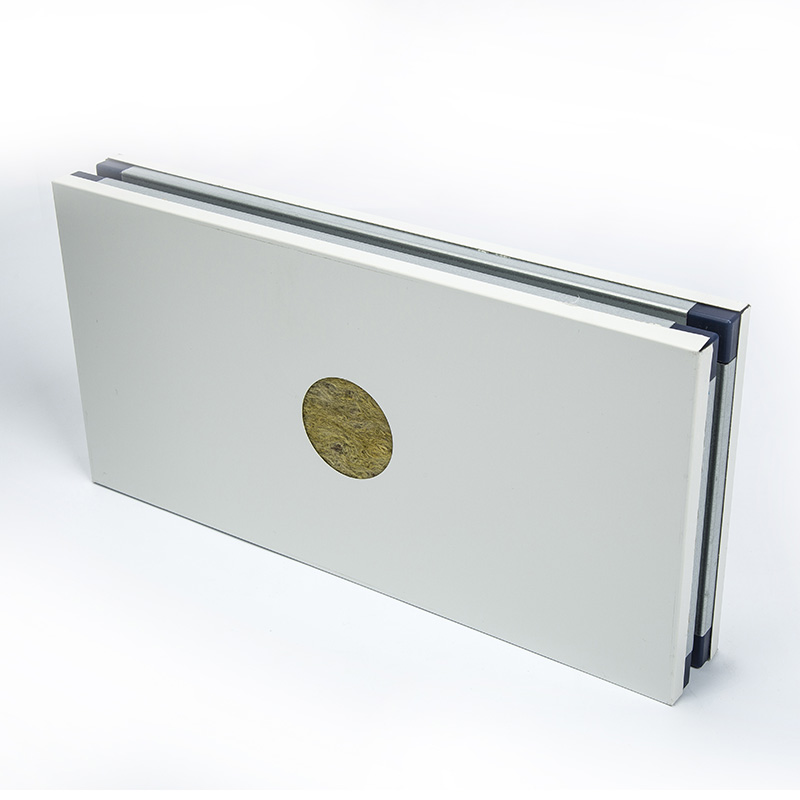

Rock Wool Sandwich Panel

- Used for wall or ceilings that have certain requirements for fire resistance.

- Very good thermal insulation, flame insulation and sound absorption properties.

- Commonly used in electronics and pharmaceutical plants.

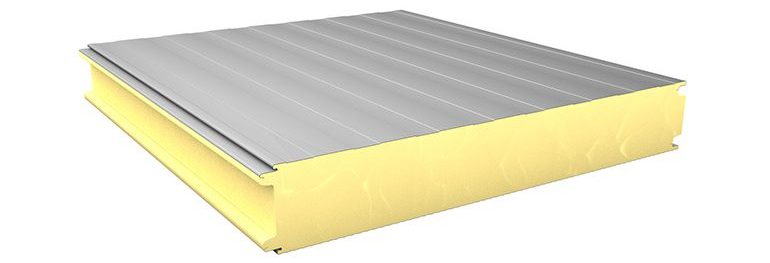

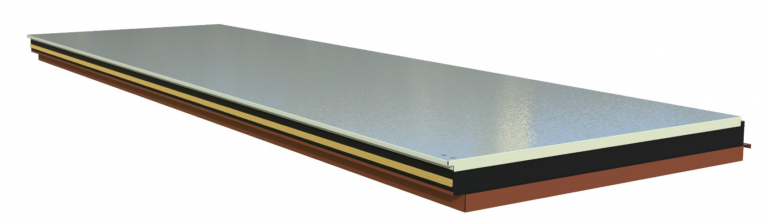

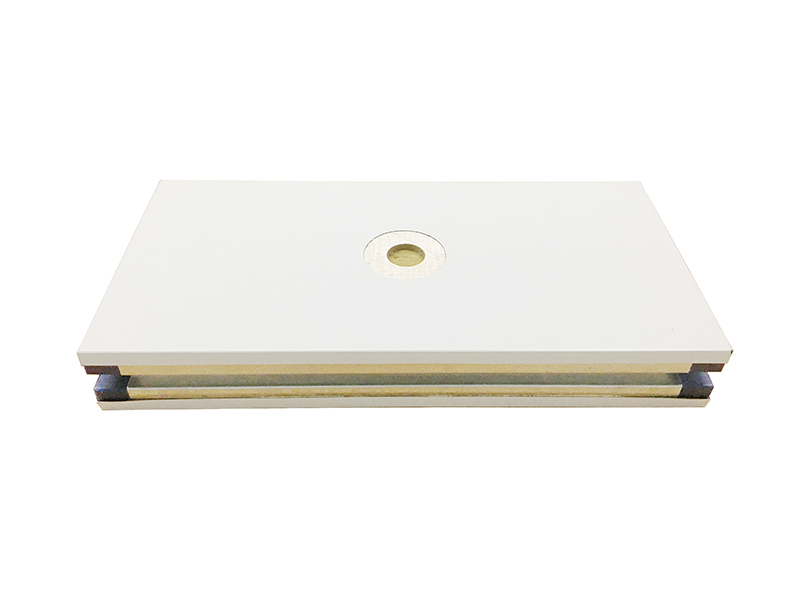

PUR / PIR sandwich Panel

- Excellent thermal insulation.

- Good strength at low density.

- Good flame retardant performance.

- Used in chemical, electronics, textile, medical, automotive, defense, aerospace, aviation.

HPL Sandwich Panel

- HPL (High Pressure Laminate) panel is a 4mm thick solid compound consisting of more than 40 layers of paper impregnated with melamine and phenolic resins.

- Thermal insulation, fire resistance.

- Easy to install.

- Nice smoothness.

Magnesium Sandwich Panel

- High temperature resistance, flame retardant, sound absorption.

- Shockproof, insect proof, water proof and moisture proof.

- Light antiseptic, non-toxic, tasteless and non-polluting.

- High strength, bending resistance, toughness.

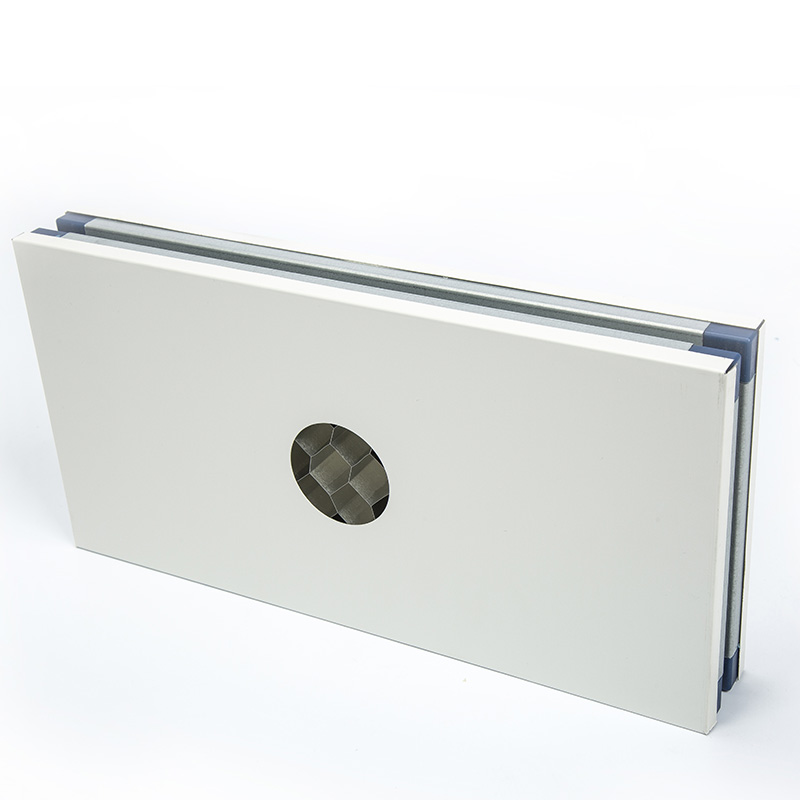

Honeycomb Sandwich Panel

- Aluminum hexagonal honeycomb has extremely high flatness and good seismic performance.

- Sound insulation, heat insulation.

- Non-flammable substances.

- Waterproof, moisture proof.

Similar Sandwich Panel Systems

Interested in our systems?

Our engineers will provide the most suitable solutions for your project.